Alaabta

Isku-xidhka Xargaha Tolan ee Tolanka, Shaashadda, Gaashaanka iyo Daabacaadda

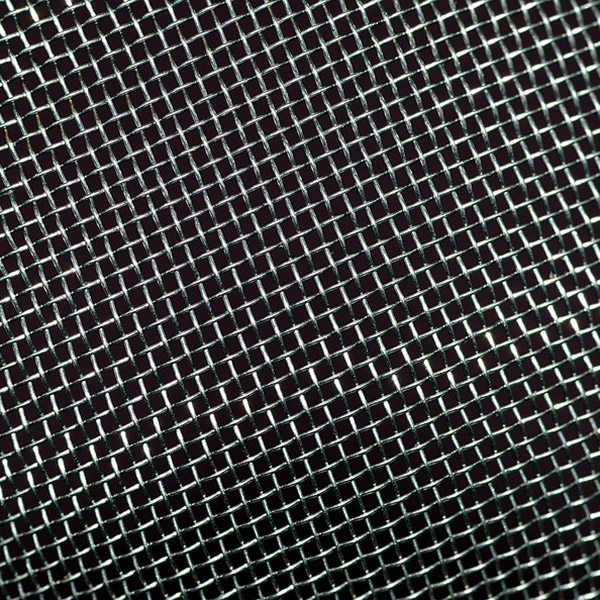

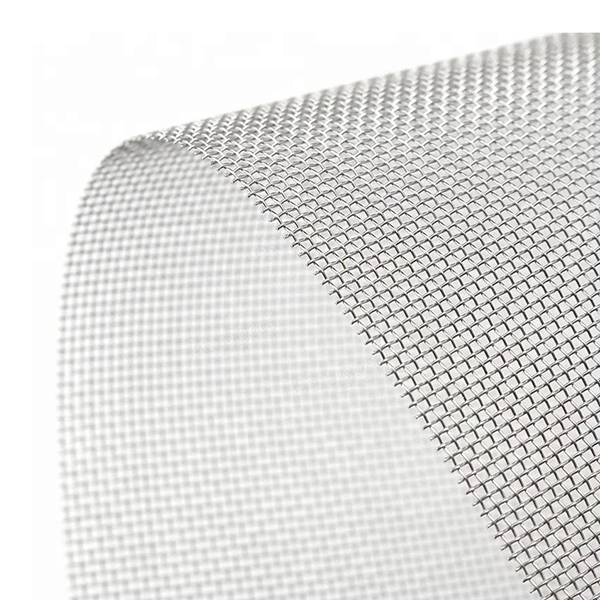

Weave Cad

Nooca ugu fudud uguna badan ee la isticmaalo oo leh meelo labajibbaaran. Waxa lagu tolaa iyada oo lagu beddelanayo siliga dunta dusheeda iyo hoosteeda siliga dunta waxana ay ogolaataa in si togan loo xakameeyo cabbirka agabka in la baaro ama la sifeeyo.

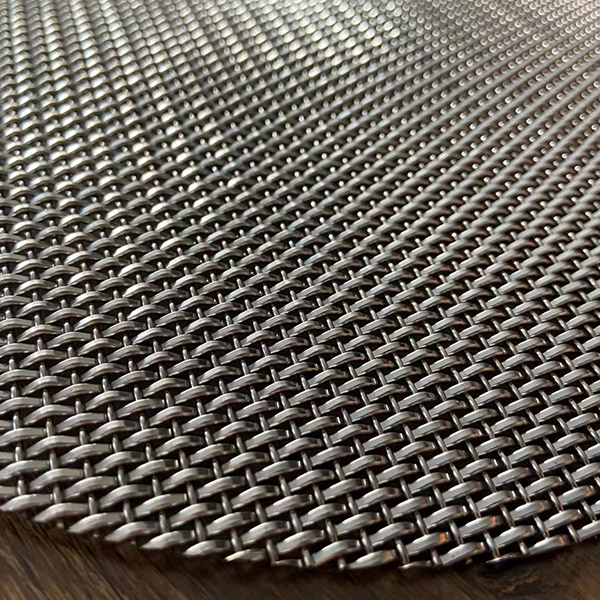

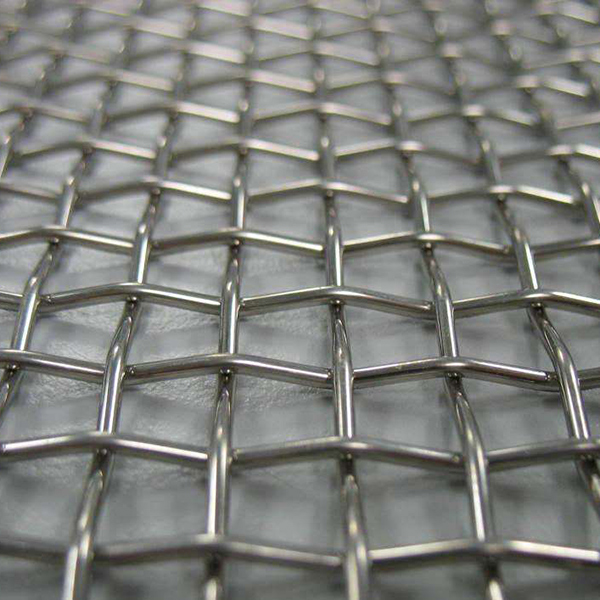

Twill Weave

Silig kasta oo tolan waxa uu si beddel ah u gudbaa oo hoos maraa 2 fiilood oo fidsan, oo is daba joog ah oo is daba jooga. Waxa loo isticmaalaa halka shabagyada khafiifka ahi ay tahay inay qaadaan culays culus.

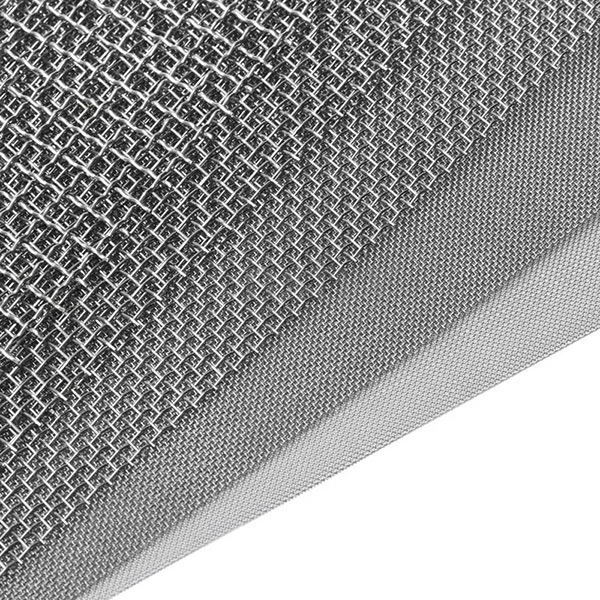

Weave Dulsan

Sidoo kale loo yaqaan tolida ballaaran, waxaa lagu door bidayaa dhar-dhogorta cad oo leh saamiga furitaanka (dhererka / ballac) ee 3: 1. Saamiyada kale waa suurtagal. Weave saddex-geesoodka ah ayaa sidoo kale diyaar u ah inuu bixiyo aagag ballaaran oo furan. Waxa loo istcimaalaa gariiraya shashadaha shaandheynta ama codsiyada kale ee naqshadaha.

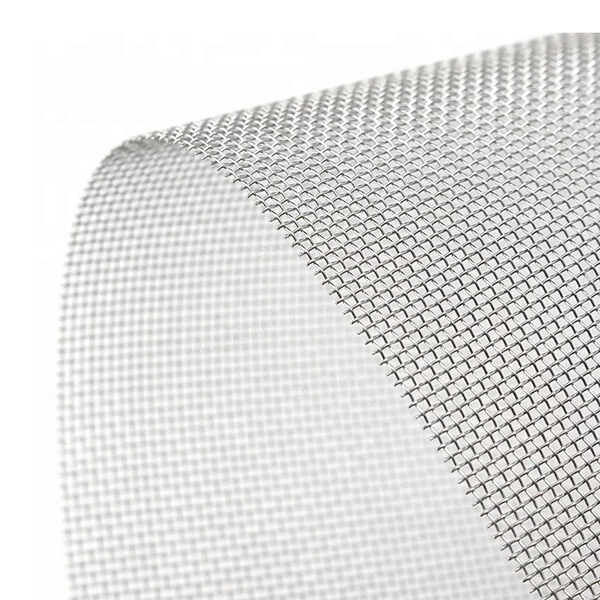

3-Hawl-gashi

Noocan tolida ah, silig kasta oo fidsan ayaa si kale u kor iyo hoos mid kasta u gudbiyaa iyo laba xargo oo isku bedbeddela. Sidoo kale, silig kasta oo tolan wuxuu u socdaa kor iyo hoos mid kasta iyo laba fiilood oo fidsan. Waxaa si weyn loogu isticmaalaa miirayaasha warshadaha, saxanadaha filter iyo dhululubada sifaynta.

5-Hawl-gashi

Noocan tolida ah, silig kasta oo fidsan ayaa kor iyo hoos u dhigaya mid kasta iyo afar silig oo lug ah iyo lidkeeda. Waxay bixisaa furin leydi ah waxayna bixisaa heerarka socodka sare. Waxa si weyn loogu isticmaalaa sifaynta batroolka & warshadaha kiimikada.

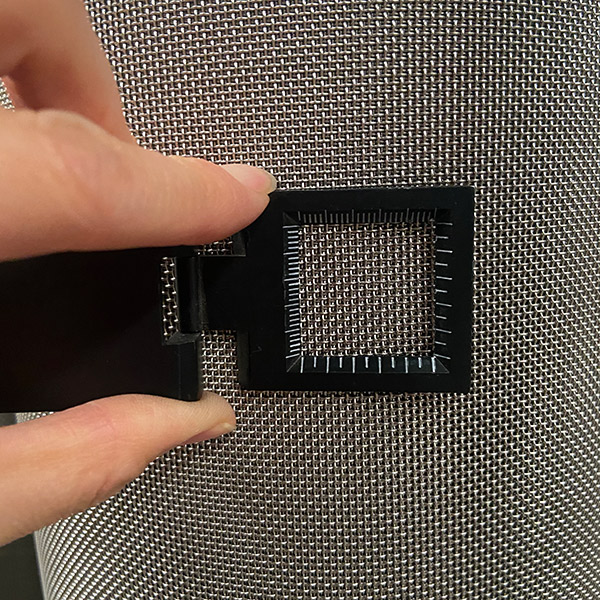

Tilmaamid

Qalab:Birta aan lahayn, SS304, SS316, SS316L, SS201, SS321, SS904, iwm. Brass, Copper, Nickel, silver, monel alloy, inconel alloy, daawaha degdega ah, birta aluminium aluminium bir ah, silig bir ah carbon steel sida 65mn, silig galvanized, iwm.

Dhexroorka siligga:0.02-2 mm

Tirada mesh:2.1-635 mesh

Ballaca daloolka:0.02-10.1 mm

Aagga baarista furan:25% - 71%

| Mesh Countt | Wire Diameter (d) | Aperture Width (w) | Furan Baaritaanka yihiina | Mdabada | Aperture Quantities 1 cm2 |

| Maya | mm | mm | % | kg/m2 | |

| 635 | 0.02 | 0.02 | 25 | 0.127 | 62500 |

| 508 | 0.025 | 0.025 | 25 | 0.159 | 40000 |

| 450 | 0.027 | 0.03 | 27.7 | 0.162 | 31388 |

| 400 | 0.027 | 0.036 | 32.7 | 0.147 | 24800 |

| 363 | 0.03 | 0.04 | 32.7 | 0.163 | 20424 |

| 325 | 0.035 | 0.043 | 30.4 | 0.199 | 16372 |

| 314 | 0.036 | 0.045 | 30.9 | 0.203 | 15282 |

| 265 | 0.04 | 0.056 | 34 | 0.212 | 10885 |

| 250 | 0.04 | 0.063 | 37.4 | 0.197 | 9688 |

| 210 | 0.05 | 0.071 | 34.4 | 0.262 | 6836 |

| 202 | 0.055 | 0.071 | 31.8 | 0.305 | 6325 |

| 200 | 0.053 | 0.074 | 34 | 0.281 | 6200 |

| 200 | 0.05 | 0.08 | 37.9 | 0.244 | 6200 |

| 188 | 0.055 | 0.08 | 35.1 | 0.285 | 5478 |

| 170 | 0.055 | 0.094 | 39.8 | 0.258 | 4480 |

| 150 | 0.071 | 0.1 | 34.6 | 0.366 | 3488 |

| 154 | 0.065 | 0.1 | 36.7 | 0.325 | 3676 |

| 200 | 0.03 | 0.1 | 61 | 0.078 | 6200 |

| 150 | 0.06 | 0.11 | 41.9 | 0.269 | 3488 |

| 130 | 0.08 | 0.112 | 34 | 0.423 | 2620 |

| 140 | 0.06 | 0.12 | 44.4 | 0.254 | 3038 |

| 120 | 0.09 | 0.12 | 32.7 | 0.49 | 2232 |

| 124 | 0.08 | 0.125 | 37.2 | 0.396 | 2383 |

| 110 | 0.09 | 0.14 | 37.1 | 0.447 | 1876kii |

| 106 | 0.1 | 0.14 | 34 | 0.529 | 1742 |

| 100 | 0.11 | 0.14 | 31.4 | 0.615 | 1550 |

| 100 | 0.1 | 0.15 | 36 | 0.508 | 1550 |

| 100 | 0.1 | 0.16 | 37.9 | 0.488 | 1550 |

| 91 | 0.12 | 0.16 | 32.7 | 0.653 | 1284 |

| 80 | 0.14 | 0.18 | 31.6 | 0.784 | 992 |

| 84 | 0.1 | 0.2 | 44.4 | 0.42 | 1094 |

| 79 | 0.12 | 0.2 | 39.1 | 0.572 | 967 |

| 77 | 0.13 | 0.2 | 36.7 | 0.65 | 919 |

| 46 | 0.15 | 0.4 | 52.9 | 0.505 | 328 |

| 70 | 0.1 | 0.261 | 52 | 0.354 | 760 |

| 65 | 0.1 | 0.287 | 54.6 | 0.331 | 655 |

| 61 | 0.11 | 0.306 | 53.6 | 0.307 | 577 |

| 56 | 0.11 | 0.341 | 56.8 | 0.283 | 486 |

| 52 | 0.12 | 0.372 | 56.8 | 0.374 | 419 |

| 47 | 0.12 | 0.421 | 60.3 | 0.342 | 342 |

| 42 | 0.13 | 0.472 | 61.2 | 0.306 | 273 |

| Mesh Countt | Wire Diameter (d) | Aperture Width (w) | Furan Baaritaanka yihiina | Mdabada | Aperture Quantities 1 cm2 |

| Maya | mm | mm | % | kg/m2 | |

| 2.1 | 2 | 10.1 | 69.7 | 3.95 | 0.68 |

| 3 | 1.6 | 6.87 | 65.8 | 3.61 | 1.4 |

| 3.6 | 2 | 5.06 | 51.3 | 6.77 | 2.01 |

| 4 | 1.2 | 5.15 | 65.8 | 2.71 | 2.48 |

| 4 | 1.6 | 4.75 | 56 | 4.81 | 2.48 |

| 5 | 1.2 | 3.88 | 58.3 | 3.38 | 3.88 |

| 5 | 1.6 | 3.48 | 46.9 | 6.02 | 3.88 |

| 6 | 0.9 | 3.33 | 62 | 2.28 | 5.58 |

| 6 | 1.2 | 3.03 | 51.3 | 4.06 | 5.58 |

| 8 | 0.7 | 2.48 | 60.8 | 1.84 | 9.92 |

| 8 | 1 | 2.18 | 46.9 | 3.76 | 9.92 |

| 8 | 1.2 | 1.98 | 38.7 | 5.41 | 9.92 |

| 10 | 0.4 | 2.14 | 71 | 0.75 | 15.5 |

| 10 | 0.5 | 2.04 | 64.5 | 1.18 | 15.5 |

| 10 | 0.6 | 1.94 | 58.3 | 1.69 | 15.5 |

| 12 | 0.4 | 1.72 | 65.8 | 0.9 | 22.32 |

| 12 | 0.5 | 1.62 | 58.3 | 1.41 | 22.32 |

| 12 | 0.65 | 1.47 | 48 | 2.38 | 22.32 |

| 14 | 0.5 | 1.31 | 52.5 | 1.65 | 30.38 |

| 16 | 0.4 | 1.19 | 56 | 1.2 | 39.68 |

| 16 | 0.5 | 1.09 | 46.9 | 1.88 | 39.68 |

| 18 | 0.4 | 1.01 | 51.3 | 1.35 | 50.22 |

| 18 | 0.5 | 0.91 | 41.7 | 2.12 | 50.22 |

| 20 | 0.3 | 0.97 | 58.3 | 0.85 | 62 |

| 20 | 0.35 | 0.92 | 52.5 | 1.15 | 62 |

| 20 | 0.4 | 0.87 | 46.9 | 1.5 | 62 |

| 20 | 0.5 | 0.77 | 36.8 | 2.35 | 62 |

| 24 | 0.36 | 0.7 | 43.5 | 1.46 | 89.28 |

| 30 | 0.25 | 0.6 | 49.7 | 0.88 | 139.5 |

| 30 | 0.3 | 0.55 | 41.7 | 1.27 | 139.5 |

| 35 | 0.25 | 0.5 | 44.4 | 1.03 | 189.9 |

| 40 | 0.2 | 0.44 | 46.9 | 0.75 | 248 |

| 40 | 0.25 | 0.39 | 36.8 | 1.18 | 248 |

| 45 | 0.25 | 0.31 | 31 | 1.32 | 313.88 |

| 50 | 0.18 | 0.33 | 41.7 | 0.76 | 387.5 |

| 50 | 0.2 | 0.31 | 36.8 | 0.94 | 387.5 |

| 50 | 0.23 | 0.28 | 29.9 | 1.24 | 387.5 |

| 60 | 0.12 | 0.3 | 51.3 | 0.41 | 558 |

| 60 | 0.16 | 0.26 | 38.7 | 0.72 | 558 |

| 60 | 0.18 | 0.24 | 33 | 0.91 | 558 |

| 70 | 0.12 | 0.24 | 44.8 | 0.48 | 759.5 |

| 80 | 0.12 | 0.2 | 38.7 | 0.55 | 992 |

Bandhiga Alaabta